Trending Products Zirconia Ceramic Part - Al2O3 Bulletproof Ceramic Plate – Guiyuan

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

Trending Products Zirconia Ceramic Part - Al2O3 Bulletproof Ceramic Plate – Guiyuan Detail:

Basic Info

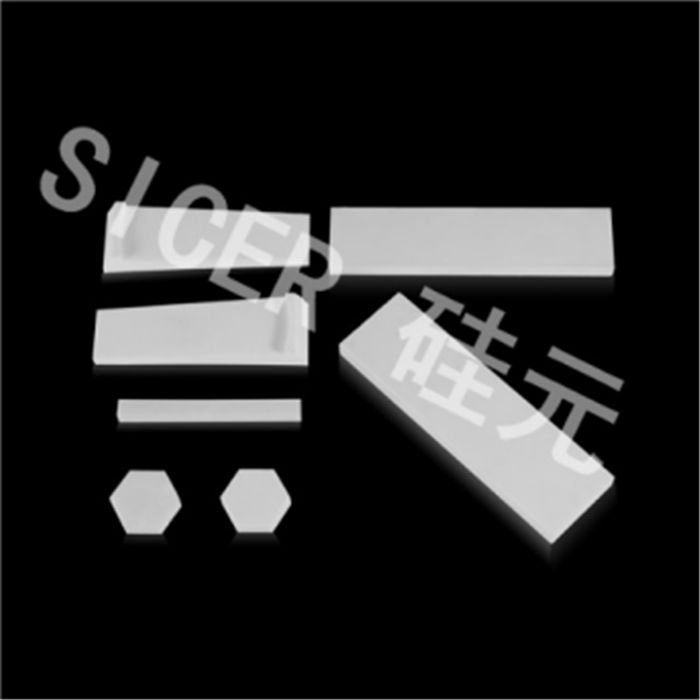

Production Name: Al2O3 Bulletproof Ceramic Plate

Application: Military Apparel/Vest

Material: Al2O3

Shape: Brick

Product description:

Al2O3 bulletproof plate is sintered under high temperature and it’s alumina content reaches 99.7%.

Advantage:

·High hardness

·Good wear resistance

·High compressive strength

·Excellent ballistic performance under high stress

Products Show

Introduce:

Bullets, fragments, stabbing with sharp objects – today’s high-risk professionals must contend with an ever-increasing range of threats. And it’s not just military and law enforcement personnel who need protection. Around the world, prison guards, cash carriers and private individuals all put their lives on the line for other people’s safety. And they all deserve first-class protective solutions. Whatever the environment, whatever the threat, our materials are developed with one objective: maximizing safety. With our innovative ballistic vest materials and solutions, we help deliver enhanced protection to users. Day after day, year after year. Meanwhile, we are also setting new standards for stab- and spike-protection products – with materials that offer unrivaled puncture and cut resistance. All while reducing weight. All while increasing comfort and enabling freedom of movement. You can be sure of that.

Such plates of uniform thickness are typically made by axial pressing to shape. In case of the alumina and silicon carbide hexagons, the bevel may be formed during the shaping process or by subsequent grinding. Parts must be perfectly flat and within narrow dimensional tolerances to reduce machining effort. They also must be completely dense, as internal porosity would reduce hardness, stiffness and ballistic performance. Inhomogeneous green density from the surface to the center of the pressed part would cause warping or inhomogeneous density after sintering. Thus, the requirements to the quality of the pressed green bodies are high. To eliminate residual porosity, such materials are frequently post-HIPed after conventional sintering. Other manufacturing processes may also be applied but will not be economically competitive to mass production by axial pressing.

Product detail pictures:

Related Product Guide:

Our commission should be to provide our customers and consumers with ideal top quality and aggressive portable digital products for Trending Products Zirconia Ceramic Part - Al2O3 Bulletproof Ceramic Plate – Guiyuan, The product will supply to all over the world, such as: Suriname, Tunisia, Ghana, we are sincerely hope to establish one good long term business relationship with your esteemed company thought this opportunity, based on equal, mutual beneficial and win win business from now till the future.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!