OEM manufacturer Semi-Conductor Ceraimc Components - Quartz Ceramic Crucible – Guiyuan

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

OEM manufacturer Semi-Conductor Ceraimc Components - Quartz Ceramic Crucible – Guiyuan Detail:

Product Details

| Type | Refractory Material |

| Material | SiO2 |

| Working Temperature | ≤1650℃ |

| Shape | Square, Pipe, etc |

Product description

Quartz ceramic has excellent thermal shock resistance performance thanks to grain composition optimization. Quartz ceramic has a small coefficient of thermal expansion, good chemical stability and resistance to glass melt corrosion.

Alumina is a kind of ceramic material that have high thermal conductivity, high abrasion resisttance, compressive strength, high temperature resistance and and thermal shock resistacne. It’s also a suitalbe material for furnace use in crucible, which is low cost compared with other refractories.

There are two kinds of material for SICER Crucible, Alumina and Zirconia.

With excellent resistance to thermal shock, corrosion, and coefficient of thermal expansion, they are widely applied to the smelting process.

Alumina crucible has good acid and alkali resistance and is suitable for melting alloy and stainless steel. The maximum working temperature can reach 1600 ℃

Zirconia Crucible has excellent resistance to acid slag, and is widely used for smelting from the super alloy and the noble metal, and the optimal operating temperature is from 1980 to 2100℃.

Applications

Aluminum oxide crucible is widely used in the following application:

Used for making parts for CVD, ion implants, photolithography, and semiconductor parts.

Used for furnaces for metallurgy industry due to its ability serving under high temperature.

Used as protector for high temperature thermal couples.

Used for chemical industry with high corrosion resisttance.

Advantage

• Low thermal expansion

• Good thermal shock resistance

• Good chemical stability

• Low bulk density

• Resistance to glass melt corrosion

• Low porosity and fine surface enhance cleaness

• Superior mechanical strength and wear resisttance

• Excellent chemical resistance to acids and others

• Consistent dimensional control

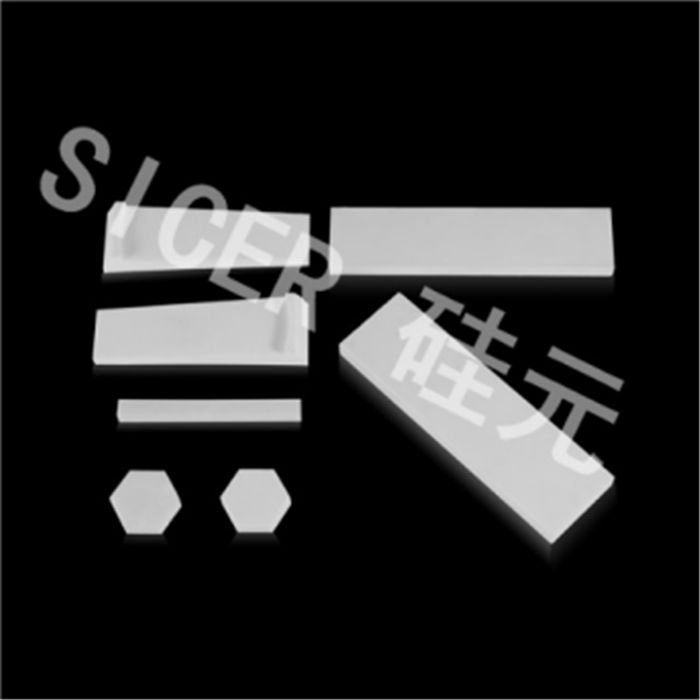

Products Show

Product detail pictures:

Related Product Guide:

We stay with the basic principle of "quality initially, services first, steady improvement and innovation to fulfill the customers" for your management and "zero defect, zero complaints" as the quality objective. To perfect our company, we give the goods while using the good high-quality at the reasonable selling price for OEM manufacturer Semi-Conductor Ceraimc Components - Quartz Ceramic Crucible – Guiyuan, The product will supply to all over the world, such as: Malaysia, Porto, Las Vegas, Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly