Paper making industry has been a conventional industry and Qinyang is a well known city in China that lead in paper making. For the past decade, its permissive development mode has caused huge pressure on environment protection. While, after years of efforts on the equipment’ updation and greening manufacturing, we have seen a quality improvement in full field around. Thus, with sclale, green, high-end in mind, Henan Yadu paper mill has invested numerous technological devices for effective utilization and environmental innovation.

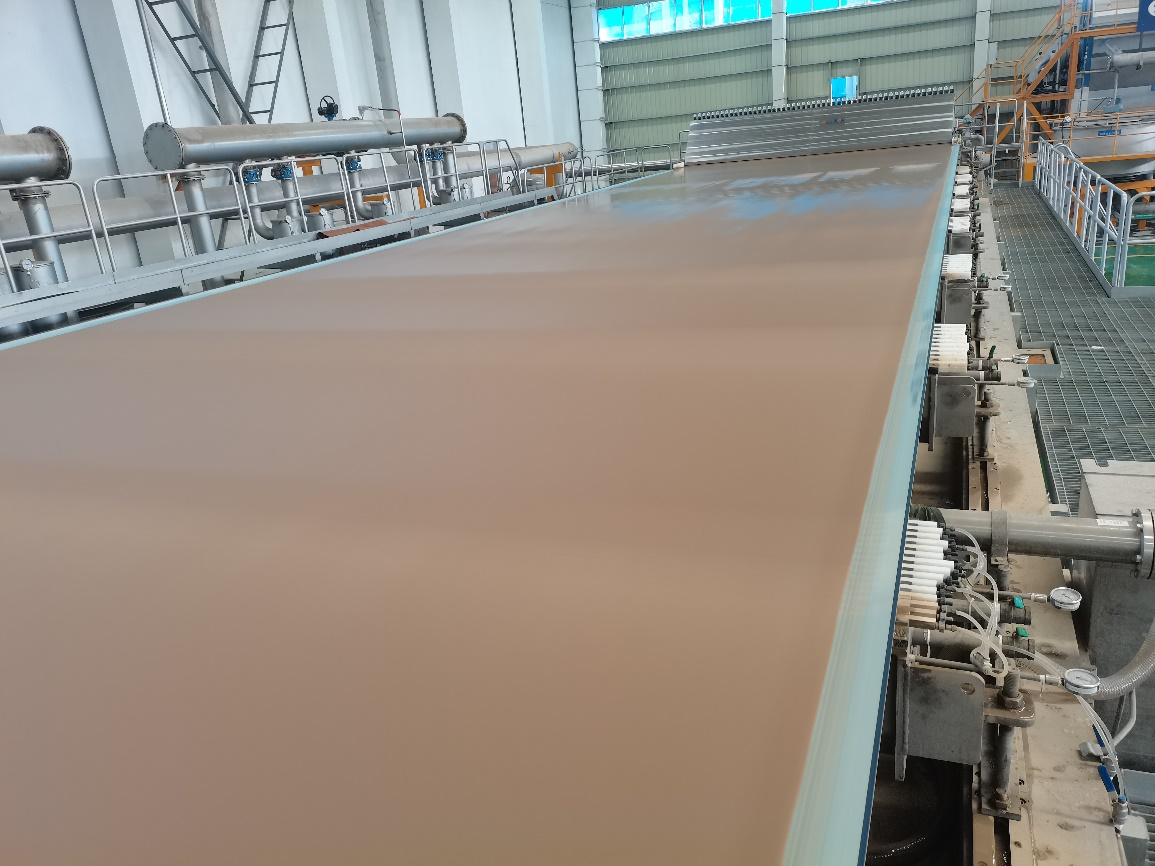

The new paper machine line that finished is for high strength corrugated paper with output of 150,000 tons. The whole paper machine is 121 meters long with designed speed of 650mpm and width of 5400mm. This project’s successful startup made this paper machine became the biggest in this area with longest width, highest speed.

SICER has provided full set of dewatering elements for this paper machine. As forming section is the “heart” of whole machine, the formation of pulp and dewtering performance have always been the biggest concern. With our high quality ceramic dewatering elements of Sub-micro 99% alumina, we supplied forming board box, hydrofoil, formation box, low vacuum box, high vacuum box and so on. The past decade has seen SICER’s dewatering equipment technology growing by leaps and bounds, especially on the energy saving and lifetime of the ceramics. With great deal of newly build project experiences, we are fully able to make the customized design for paper machines in different speed and paper type. After adopting intelligent, cost-effective and sustainable process for our production, the best quality products has been also guaranteed.

SICER has provided full set of dewatering elements for this paper machine. As forming section is the “heart” of whole machine, the formation of pulp and dewtering performance have always been the biggest concern. With our high quality ceramic dewatering elements of Sub-micro 99% alumina, we supplied forming board box, hydrofoil, formation box, low vacuum box, high vacuum box and so on. The past decade has seen SICER’s dewatering equipment technology growing by leaps and bounds, especially on the energy saving and lifetime of the ceramics. With great deal of newly build project experiences, we are fully able to make the customized design for paper machines in different speed and paper type. After adopting intelligent, cost-effective and sustainable process for our production, the best quality products has been also guaranteed.

Post time: Oct-13-2021