Manufacturing Companies for Ceramic Ball Valves - Ceramic Valves – Guiyuan

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

Manufacturing Companies for Ceramic Ball Valves - Ceramic Valves – Guiyuan Detail:

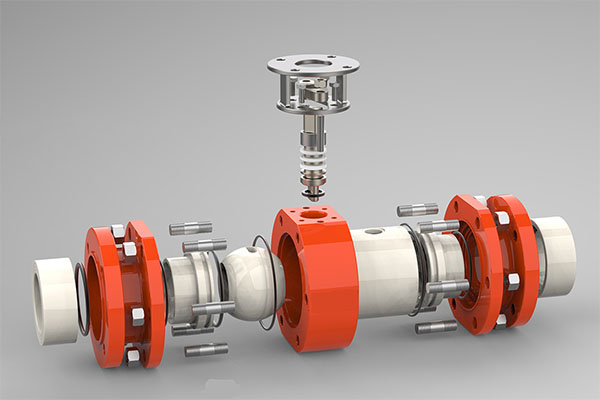

Introduction

1. Sicer has rich ceramic material system, and can provide a variety of ceramic materials and self-lubricating properties materials;

2. Under the same working conditions, the service life of ceramic valve is more than 5-10 times that of ordinary metal valve;

3. Using the unique facing up technology of ceramic ball valve to make ceramic hard seal be reliable and stable;

4. Rich experience in valve ceramic material selection, can match the optimal selection scheme according to the working conditions (pressure, frequency, medium, etc.);

5. Electric/ pneumatic/ remote control on-off switch, optimum structural design and production precision to avoid abrupt breakdown and ensure the valve opening and closing freely and the stability of torque;

6. Sicer has developed a series of new ceramic valve products, such as ceramic C valve, ceramic slide valve and ceramic angle valve, and successfully promoted them to the market;

7. Widely used in various acid and alkali fluid, high temperature steam, mud, crude oil transportation and storage system. It is an ideal substitute for titanium metal valve and Monel valve under strong corrosion conditions. Tens of thousands of ceramic valves of various types have been applied.

8. Continuous technical consultation service before and after sales.

Application Cases

The world’s largest single coal-to-oil project

A new project of a domestic chemical enterprise

Basic Info

1. According to the working condition and some other particulare working condition of plunger pump, SICER would design special ceramic technique proposal and module choosing.

2. Both flexible and rigid seal can be probided for various requirement.

3. Paticular ceramic materials and self lubrication material can be supplied for matchaing of friction pair to reduce further abrasion.

4. Electric, pneumatic, and remote control can be done with smooth separating combing of valves.

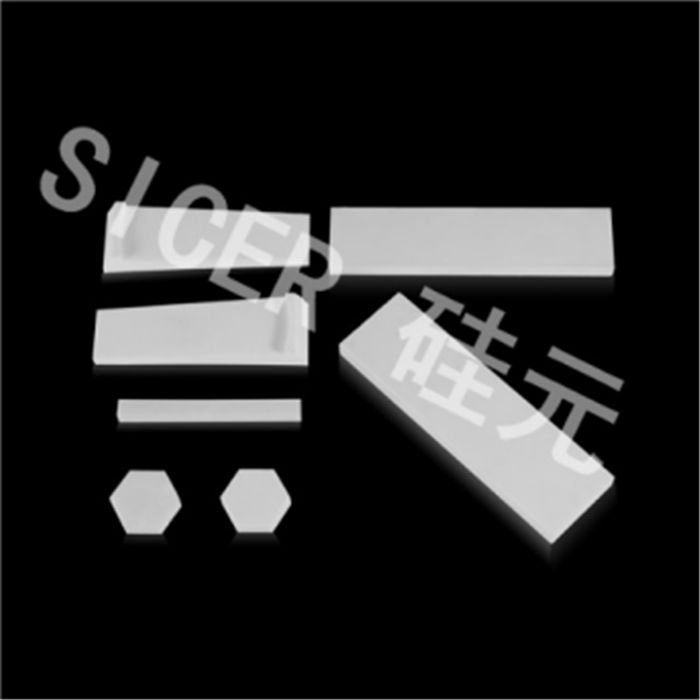

Products Show

Different Ceramic Materials for different related application.

1. Alumina (Al2O3) is one of the most economic ceramic materials, it has great corrosion and abrasion resistance properties.

2. Zirconium (ZrO2) is the highest strength and toughness at room temperature of all engineered ceramics. But this ZrO2 has operating temperature limitation, the Max temperature is 320 degC.

3. Silicon Nitride is one of great ceramic material especially used for high temperature application, special housing and ceramic parts permit solution temperature up to 950 degC.

4. Silicon Carbide is the most hardness material of all engineered ceramics, in the other word SiC hardness next to Diamond. But very low fracture toughness of SiC is a big weakness for ceramic parts, it’s easy be broken.

Product detail pictures:

Related Product Guide:

With our leading technology also as our spirit of innovation,mutual cooperation, benefits and advancement, we'll build a prosperous future together with your esteemed organization for Manufacturing Companies for Ceramic Ball Valves - Ceramic Valves – Guiyuan, The product will supply to all over the world, such as: Swedish, Ukraine, Turkmenistan, They're durable modeling and promoting well all over the world. Under no circumstances disappearing key functions in a brief time, it's a should for you personally of fantastic quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the business make an awesome efforts to expand its international trade, raise its enterprise. rofit and improve its export scale. We are confident that we'll have a vibrant prospect and to be distributed all over the world in the years to come.

We have been looking for a professional and responsible supplier, and now we find it.