Factory Free sample Foam Ceramic - OEM/ODM Manufacturer China Zirconia Ceramic Foam Filter for Purifying The Molten Steel – Guiyuan

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

Factory Free sample Foam Ceramic - OEM/ODM Manufacturer China Zirconia Ceramic Foam Filter for Purifying The Molten Steel – Guiyuan Detail:

Fast and superior quotations, informed advisers to help you choose the correct merchandise that suits all your requirements, a short generation time, responsible quality control and different services for paying and shipping affairs for OEM/ODM Manufacturer China Zirconia Ceramic Foam Filter for Purifying The Molten Steel, Our goods love excellent popularity among the our clients. We welcome consumers, small business associations and good friends from all parts with the entire world to contact us and look for cooperation for mutual advantages.

Fast and superior quotations, informed advisers to help you choose the correct merchandise that suits all your requirements, a short generation time, responsible quality control and different services for paying and shipping affairs for China Ceramic Foam Filter, Zirconia Ceramic Filter, Customer satisfaction is our goal. We’re looking forward to cooperating with you and providing our best services in your case. We warmly welcome you to contact us and remember to feel free to contact us. Browse our online showroom to see what we can do for you. And then E-mail us your specifications or inquiries today.

As a high-quality supplier of ceramic filter, SICER specilized in the manufacture of products in four kinds of materials, which are silicon carbide(SICER-C), aluminum oxide(SICER-A), zirconium oxide(SICER-Z) and SICER-AZ. Its unique structure of three-dimensional network can effectively remove the impurities from the molten metal, which can improve the product performance and microstructure. SICER ceramic filter has been widely used in the nonferrous metal filtration and casting industry. With orientation of market demand, SICER has been always focused on the R&D of new products.

Ceramic foam filters are mainly used in the filtration of aluminum, copper, steel, steel alloys and iron casting. The ceramic foam filter has a very high volumn of porosity- above 90%, and very high area to trap inclusions. With the excellent resistance to attack and corrosion form molten metal, the filters can effectively remove inclusions, reduce trapped gas and provide laminar flow, so that the filtered metal is cleaner with higher quality, less scrap, and fewer defects, all of which contribute to better performance. It redues the turbulence during casting and prevents foreign matter from entering the casting.

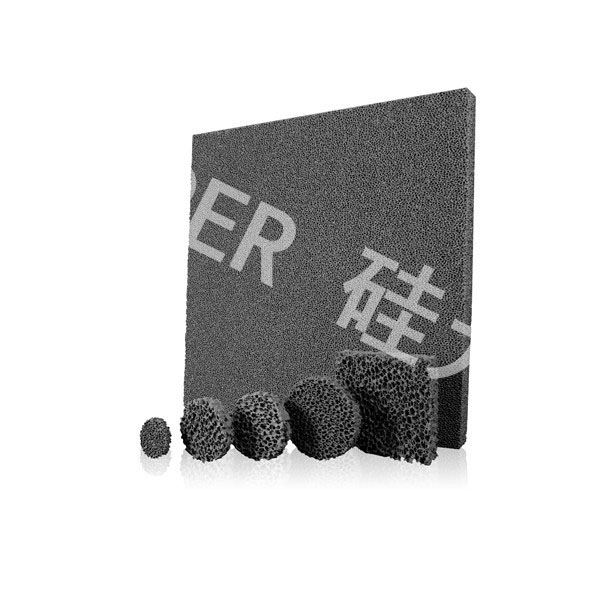

Silicon Carbide Filter

| Type | Refractory Material |

| Materials | SiC |

| Refractoriness (℃) | ≤1500 |

| Color | Grey Black |

| Pore (ppi) | 10-60 |

| Size | Customized |

| Shape | Square, Rectangle,Round etc. |

Silicon carbide filter is produced from high quality silicon carbide micro powder based on unique molding technique. It is suitable for iron castings production below 1500℃ because of its excellent thermal stability and good thermal shock resistance.

Advantage

• Excellent thermal stability

• High porosity

• Excellent absorption capability to reduce inclusion

• A wide range of dimension and pore diameter options

• Good thermal shock resistance

• Suitable for iron castings production below 1500℃

Key Specifications/Special Features

| Performance Parameter | |||

| Compress Strength (MPa) | Porosity(%) | Bulk Density(g/cm³) | Applied Temp ℃ |

| ≥1.2 | 80-87 | ≤0.5 | ≤1500 |

| Capacity | |||

| Grey Iron | 4Kg/cm2 | Ductile iron | 1.5Kg/cm2 |

Products Show

Aluminium Oxide Filter

| Type | Refractory Material |

| Materials | Al2O3 |

| Refractoriness (℃) | ≤1350 |

| Color | White |

| Pore (ppi) | 10-60 |

| Size | Customized |

| Shape | Square, Rectangle,Round etc. |

Aluminium Oxide Filter

Aluminium oxide filter is mainly used in the filtration of aluminium, aluminium alloy and molten metal under 1350℃, can solve the internal defects and sensibility problems within aluminium alloy products and reduce reject rate.

Whole range of porosities from PPI 10 to PPI 60 can be provided.

Filters in all commen sizes: 7x7x2’’, 9x9x2’’, 12x12x2’’. 15x15x2’’, 17x17x2’’, 20x20x2’’, 23x23x2’’.

Advantage

• Eco-friendly production technique

• High surface strength

• A wide range of dimension and pore diameter options

• Better flow performance

• Effectively remove inclusion and reduce reject rate

• Beveled edges and compressible gasket

Key Specifications/Special Features

| Performance Parameter | ||||

| Type | Compress Strength (MPa) | Porosity (%) | Bulk Density (g/cm³) | Applied Temp ℃ |

| SICER-A | ≥0.8 | 80-90 | 0.4~0.5 | 1260 |

| Specification and Capacity | ||||

| Size mm( inch) | Flow(kg/min) | Capacity(≤t) | ||

| 432*432*50(17’) | 180~370 | 35 | ||

| 508*508*50(20’) | 270~520 | 44 | ||

| 584*584*50(23’) | 360~700 | 58 | ||

Products Show

Zirconia Oxide Filter

| Type | Refractory Material |

| Materials | ZrO2 |

| Refractoriness (℃) | ≤1750 |

| Color | Yellow |

| Pore (ppi) | 10-60 |

| Size | Customized |

| Shape | Square, Rectangle,Round etc. |

Product description

Zirconium oxide filter is produced from high purity ziconia based on advanced production technique. It is intended for use in the filtration of stainless steel, carbon steel and other hot alloy melt below 1750℃, can improve qualified product rate of casts and reduce mould wear.

Advantage

• High purity zironia as raw material

• Advanced production technique

• A wide range of dimension and pore diameter options

• Excellent mechanical property and no slag

• High thermal shock resistance

• Effectively reduce reoxidation and subsurface defect

• Effectively filter non-metallic particles, slag

• Reduce mould wear and simplify gating system

Key Specifications/Special Features

| Performance Parameter | ||||

| Type | Compress Strength (MPa) | Porosity (%) | Bulk Density (g/cm³) | Applied Temp ℃ |

| SICER-Z | ≥2.5 | 77-83 | ≤1.2 | ≤1750 |

| Capacity | ||||

| Carbon steel | 1.5-2.5Kg/cm2 | Stainless steel | 2.0-3.5Kg/cm2 | |

Products Show

Fast and superior quotations, informed advisers to help you choose the correct merchandise that suits all your requirements, a short generation time, responsible quality control and different services for paying and shipping affairs for OEM/ODM Manufacturer China Zirconia Ceramic Foam Filter for Purifying The Molten Steel, Our goods love excellent popularity among the our clients. We welcome consumers, small business associations and good friends from all parts with the entire world to contact us and look for cooperation for mutual advantages.

OEM/ODM Manufacturer China Ceramic Foam Filter, Zirconia Ceramic Filter, Customer satisfaction is our goal. We’re looking forward to cooperating with you and providing our best services in your case. We warmly welcome you to contact us and remember to feel free to contact us. Browse our online showroom to see what we can do for you. And then E-mail us your specifications or inquiries today.

Product detail pictures:

Related Product Guide:

Every single member from our large efficiency revenue team values customers' wants and company communication for Factory Free sample Foam Ceramic - OEM/ODM Manufacturer China Zirconia Ceramic Foam Filter for Purifying The Molten Steel – Guiyuan, The product will supply to all over the world, such as: Benin, Montpellier, Lahore, Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant experienced knowledge, to develop advanced production equipment and production process , to create the first-call quality goods, reasonable price , high quality of service , quick delivery , to present you create new value .

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.