SICER – Ceramic Plunger

Short Description:

1.According to the working condition and some other particulare working condition of plunger pump, SICER would design special ceramic technique proposal and module choosing.

2.Both flexible and rigid seal can be probided for various requirement.

3.Various ficion pair are available between ceramics, rubber, polyurethane or PTFE acquire longer working life.

4.SICER fully considered the dedormation and loosening of components of plunger during manufacturing, SICER would provide well –developed experience and reference data.

Product Detail

Product Tags

Introduction

1. Ceramic plunger can meet the requirements of pressure, temperature, wear, corrosion of the comprehensive working conditions, the service life is 5-10 times of ordinary metal plunger;

2. According to the plunger pump conditions (pressure, frequency, temperature, medium, flow rate) and ceramic process, SICER can provide technical solutions and material selection;

3. Mature ceramic plunger processing technology, ensure the plunger dimension tolerance, roundness, straightness, coaxiality and other shape tolerance and surface roughness mirror effect;

4. Ceramic plunger performance are beyond the industry standards;

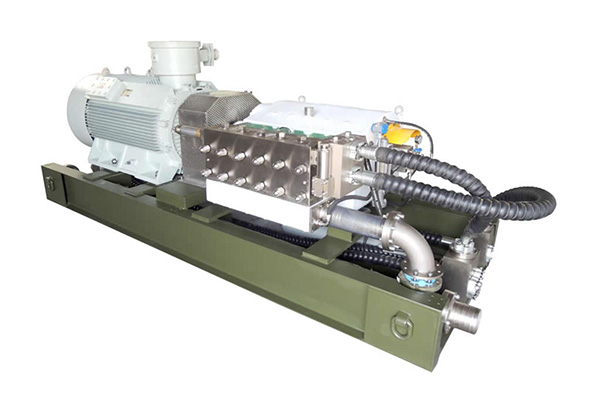

5. The products are widely used in many fields, like oilfield high pressure water injection pump, coal mine emulsion pump, high pressure cleaning pump, reciprocating pump and so on;

6. More than 20,000 ceramic plungers play a stable role in various fields;

7. Continuous technical consultation service before and after sales.

Application Cases

Used in water injection pump of a project of Shanxi coalbed methane of PetroChina

Used in coal mine emulsion pump

Basic Info

1. According to the working condition and some other particulare working condition of plunger pump, SICER would design special ceramic technique proposal and module choosing.

2. Both flexible and rigid seal can be probided for various requirement.

3. Various ficion pair are available between ceramics, rubber, polyurethane or PTFE acquire longer working life.

4. SICER fully considered the dedormation and loosening of components of plunger during manufacturing, SICER would provide well –developed experience and reference data.

5. Sealing cleareance of ceramic plunger is 5-10 times higher than matellic plunger.

Products Show