Al2O3 Wear-resistance Ceramic Sheet

Short Description:

Production Name: Al2O3 Wear-resistance Ceramic Sheet

Type: Structure Ceramic

Material: Al2O3

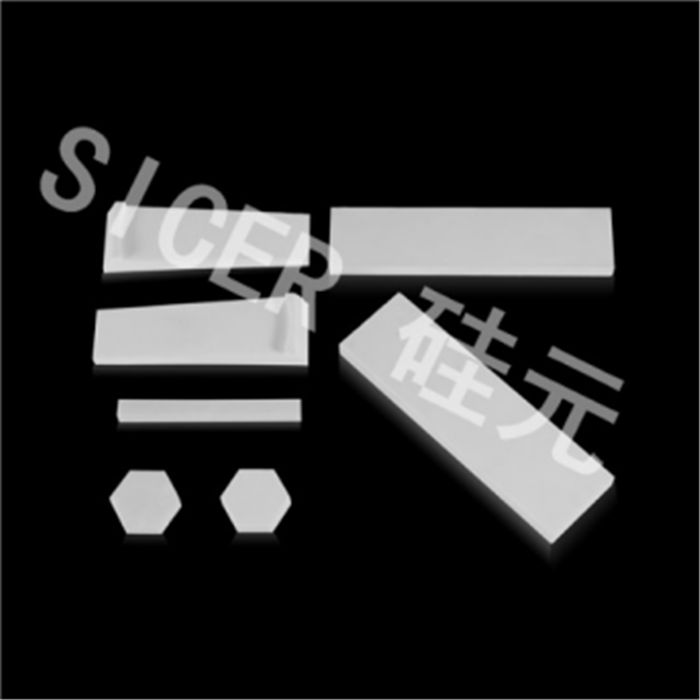

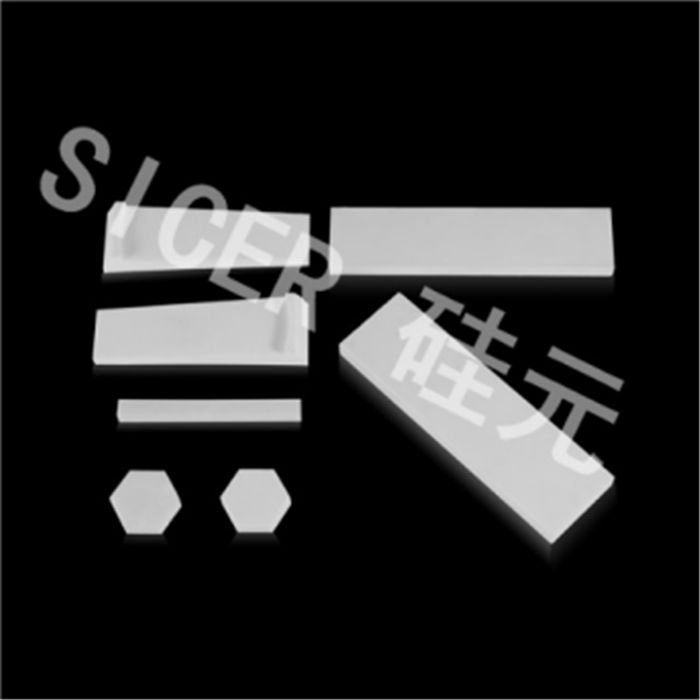

Shape: Brick, Pipe, Circle

Product Detail

Product Tags

Basic Info

Production Name: Al2O3 Wear-resistance Ceramic Sheet

Type: Structure Ceramic

Material: Al2O3

Shape: Brick, Pipe, Circle

Product description:

Aluminium oxide wear-resistance ceramic sheet is sintered under high temperature with over 99% alumina content.

Alumina ceramic liner tile has charaters of abrasive & wear resistance, corrosion resistance, high temperature resistance,low weight, easy installation.which can effectively protect industry material handling machines against wear damage. Especially applied in mining, port, cement, steel plant, power generation industry etc.

As industry ceramic manufacturer, SICER ceramic tile liner including 92% Al2O3, 95% Al2O3, Al2O3+ZrO2 compostion series, and different shape tiles including plain tile, weldable tile, trapezoidal tile, curved & lock tile, engineered tile with special geometries can meet your different wear solution requirement.

SICER can offer ideal ceramic alumina liner tile scheme according to customer's different working environment and industrial. And accept customized abrasion resistant tiles.

Advantage:

·Homogeneous microscopic structure

·High mechanical strength

·Good conductivity

·High temperature resistance

·High wear resistance

·Acid and alkali resistance

Properties of Alumina/Aluminum Oxide (Al2O3)

1. Very good electrical insulation (1x1014 to 1x1015 Ωcm)

2. Moderate to extremely high mechanical strength (300 to 630 MPa)

3. Very high compressive strength (2,000 to 4,000 MPa)

4. High hardness (15 to 19 GPa)

5. Moderate thermal conductivity (20 to 30 W/mK)

6. High corrosion and wear resistance

7. Good gliding properties

8. Low density (3.75 to 3.95 g/cm3)

9. Operating temperature without mechanical load 1,000 to 1,500°C.

10. Bioinert and food compatible

Alumina ceramic at present can be divided into high purity type and ordinary type two kinds.Wearproof plate type high purity alumina ceramic Al2O3 content in more than 99.9% of the ceramic material, due to the sintering temperature up to 1650-1990 ℃, the transmission wavelength of 1~ 6 microns, usually made from molten glass to replace platinum crucible: using alkali metal corrosion resistance is used as the transmission of light and sodium lamp tube;In the electronic industry can be used as a substrate integrated with high-frequency insulation.Ordinary aluminum oxide wear resistant ceramics department according to the Al2O3 content is divided into 99 porcelain, 95 porcelain, 90 porcelain, 85 porcelain, and other varieties, sometimes Al2O3 content in 80% or 75% are classified as ordinary aluminum oxide wear resistant ceramics series.99 alumina ceramic materials used in production, resistant to high temperature crucible furnace pipe and special wear-resistant materials, such as ceramic bearings, seals and water valve, etc.;95 alumina ceramics is mainly used as corrosion resistance, abrasion resistance parts;Because in 85 China often mixed with part of talc, improved the electric properties and the mechanical strength, with molybdenum, niobium, tantalum metal sealing, some used for electric vacuum devices.

Products Show